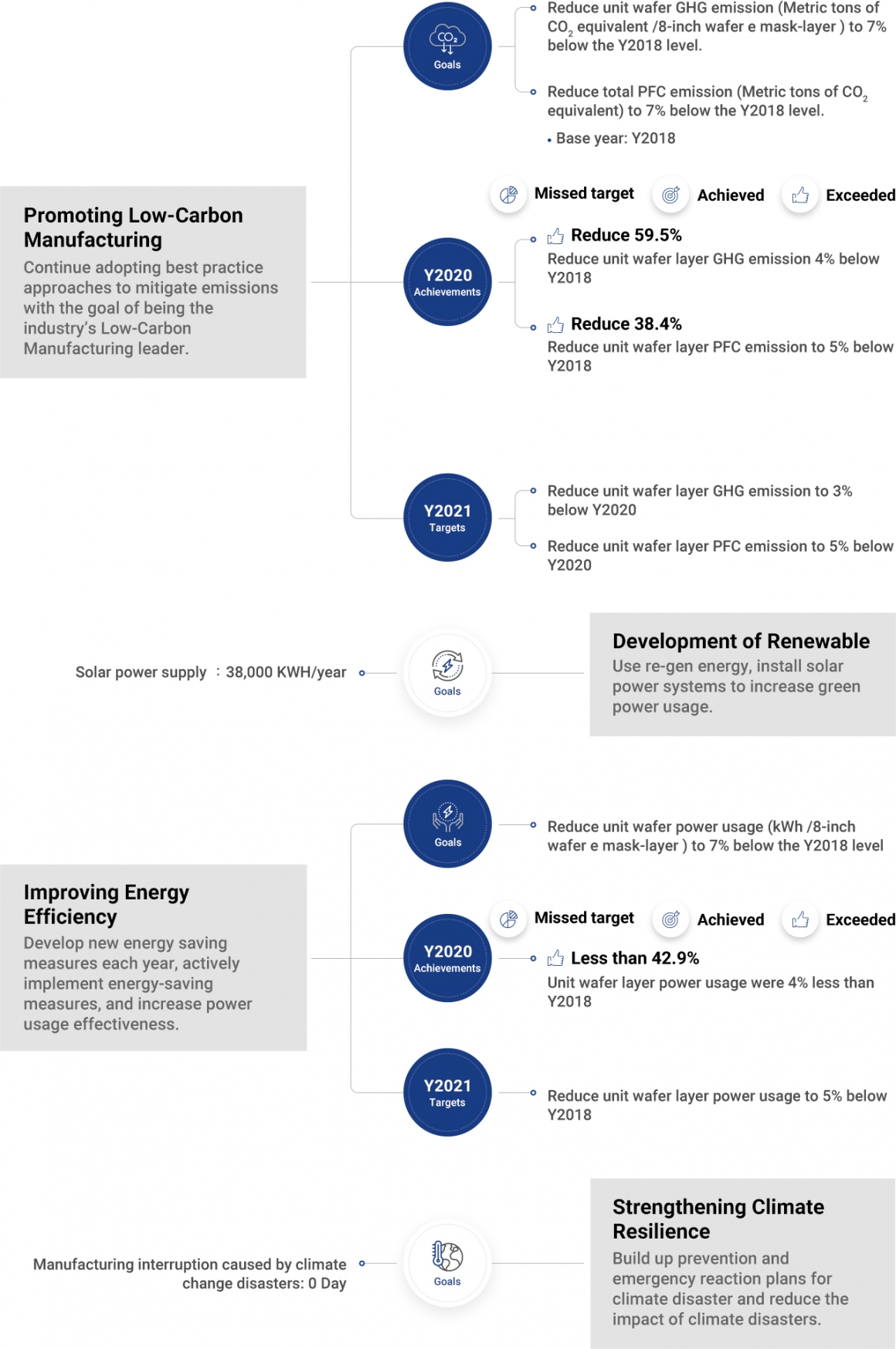

Climate Change and Energy Management

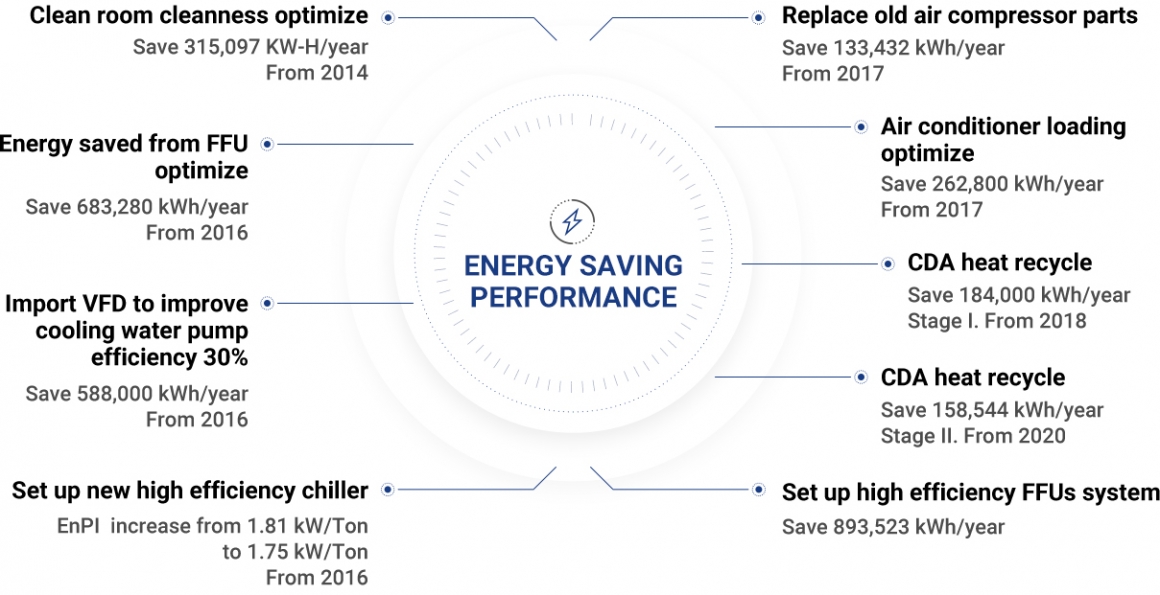

Energy Saving Performance

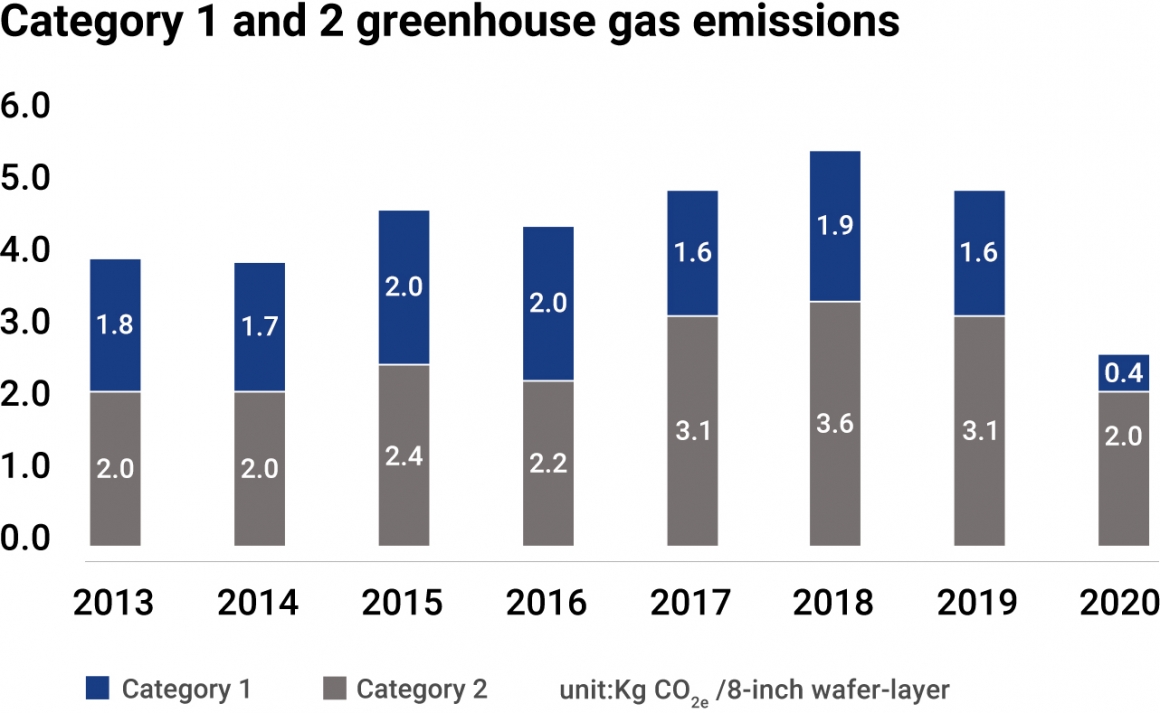

Greenhouse Gas Inventory

VisEra establish greenhouse gas inventory since 2013. Shall complete scope 1 and 2 greenhouse gas inventories for the previous year and through the external audit of a third-party organization with ISO 14064-1 verification then report to tsmc to combine.

VisEra’s green house gas emission is 38,069 tons CO2e in 2020. Main contribution comes from the power emission of category 2 , about 79% of the company's total emissions. 2nd comes from PFCs used in process in category 1 and direct emissions by fuel used in public systems, about 21%.

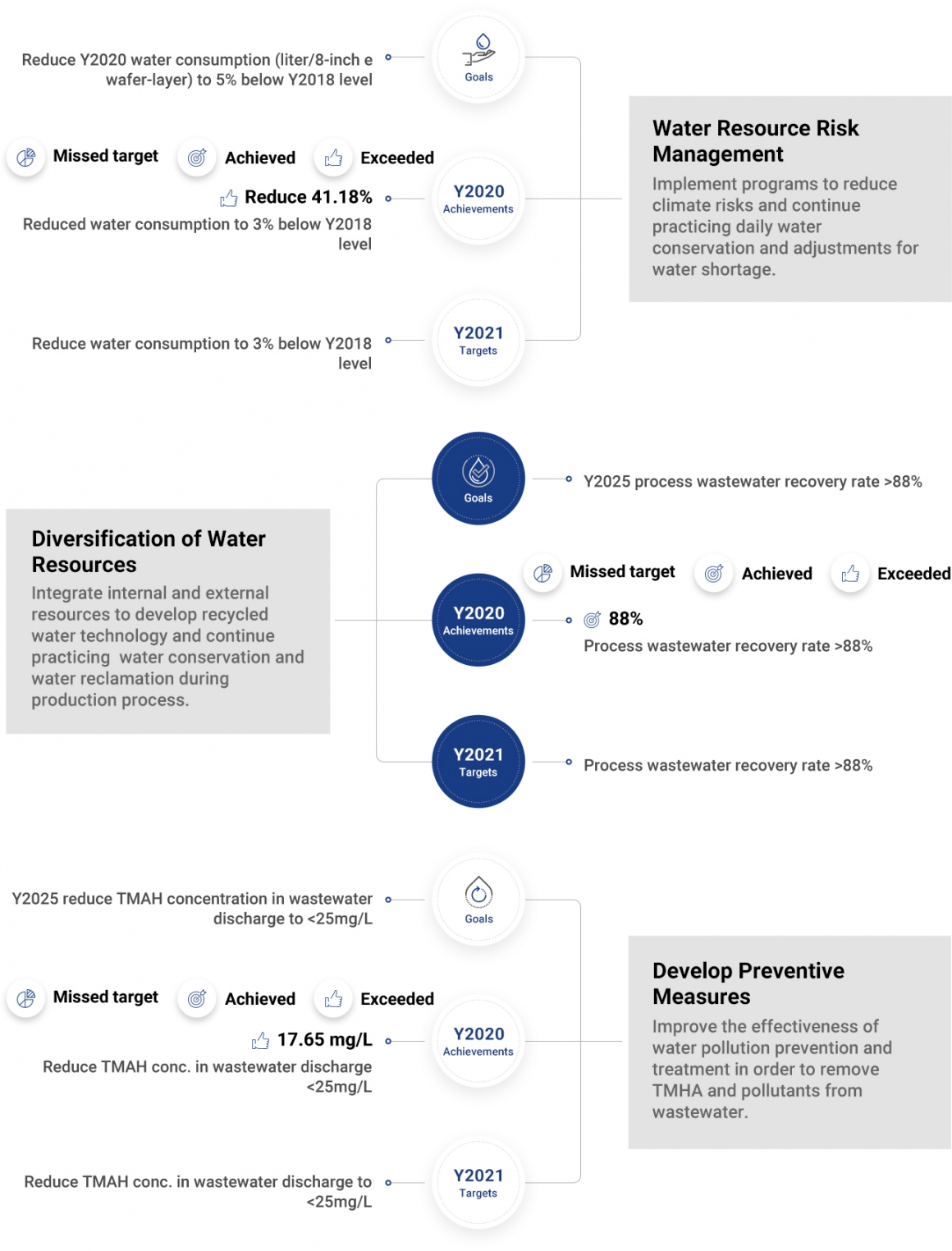

Water Management

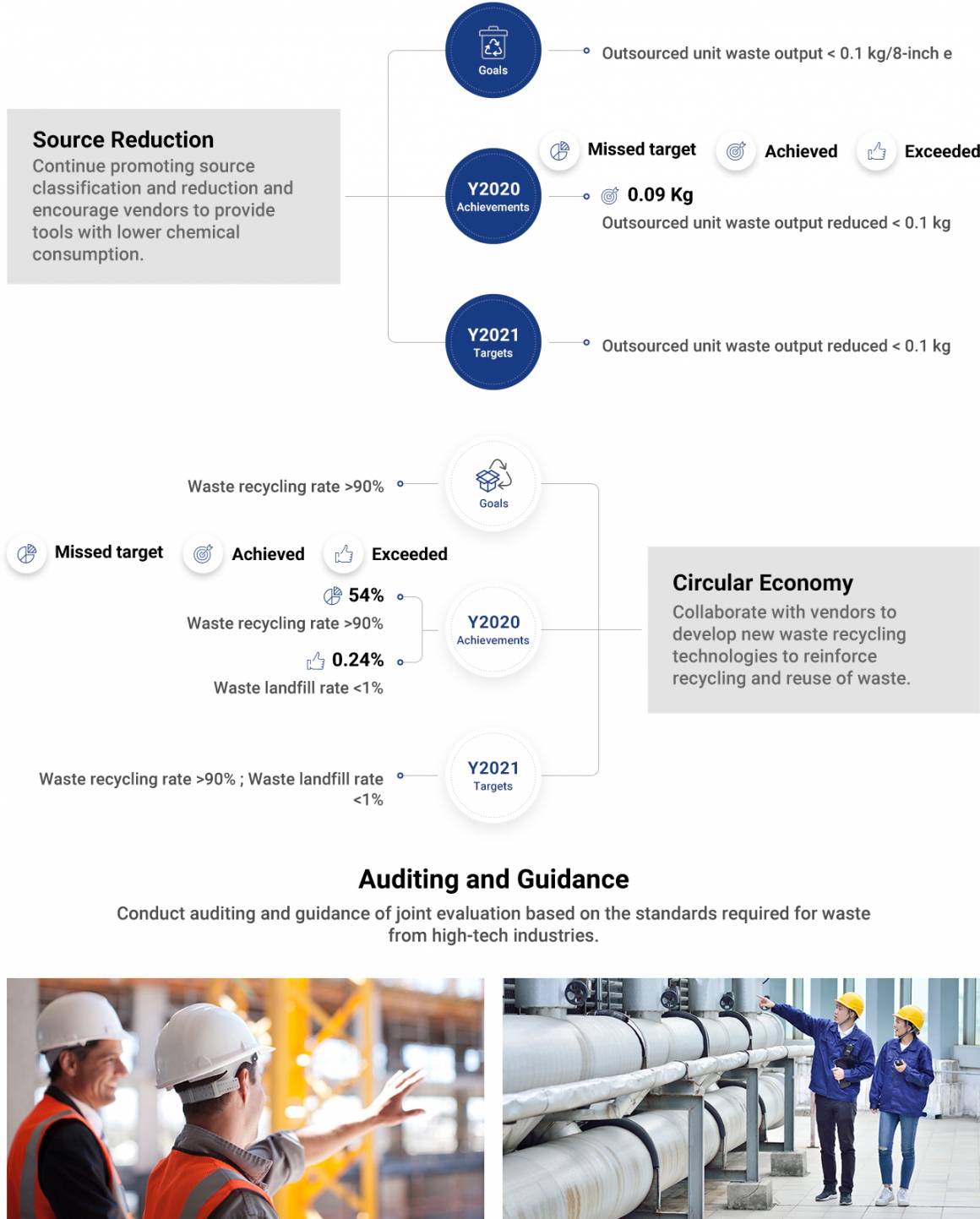

Waste Management

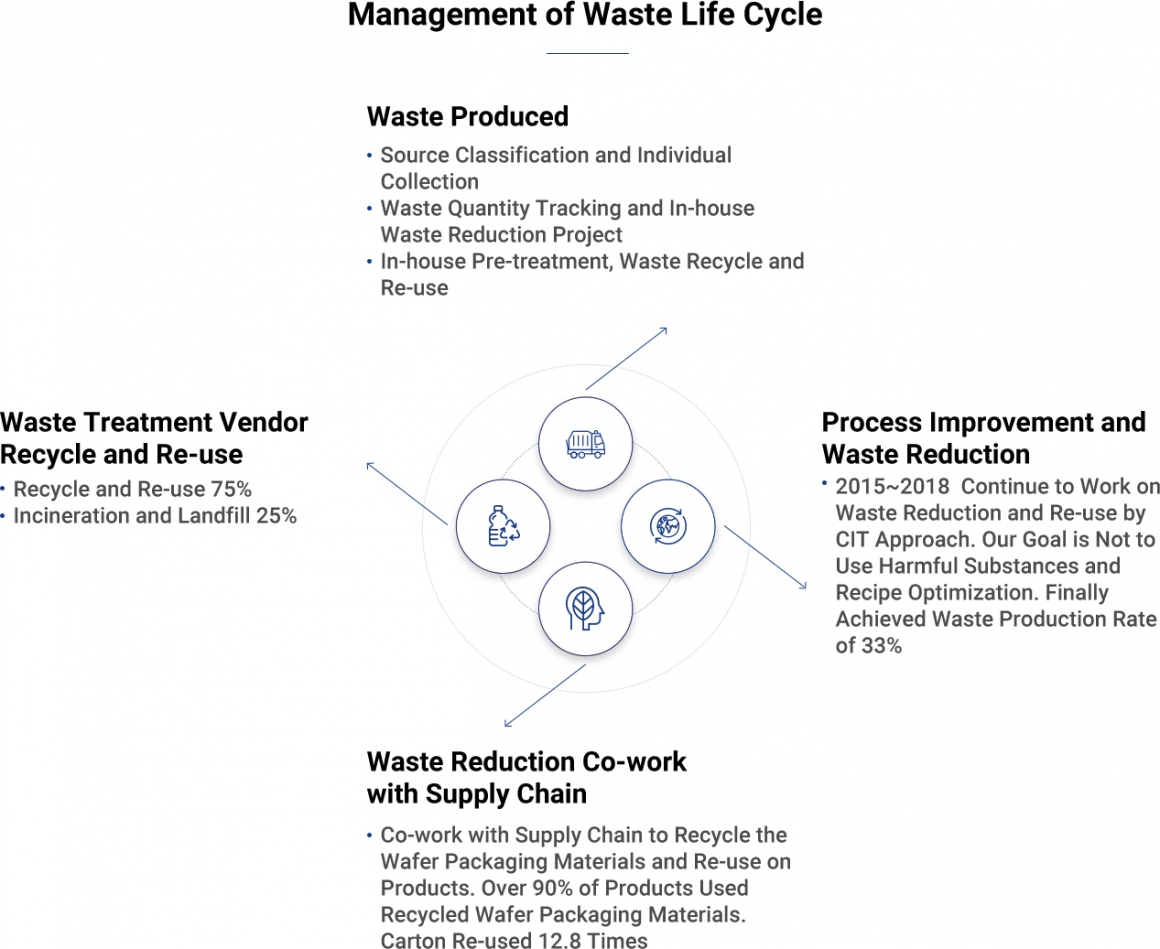

Management of Waste Life Cycle

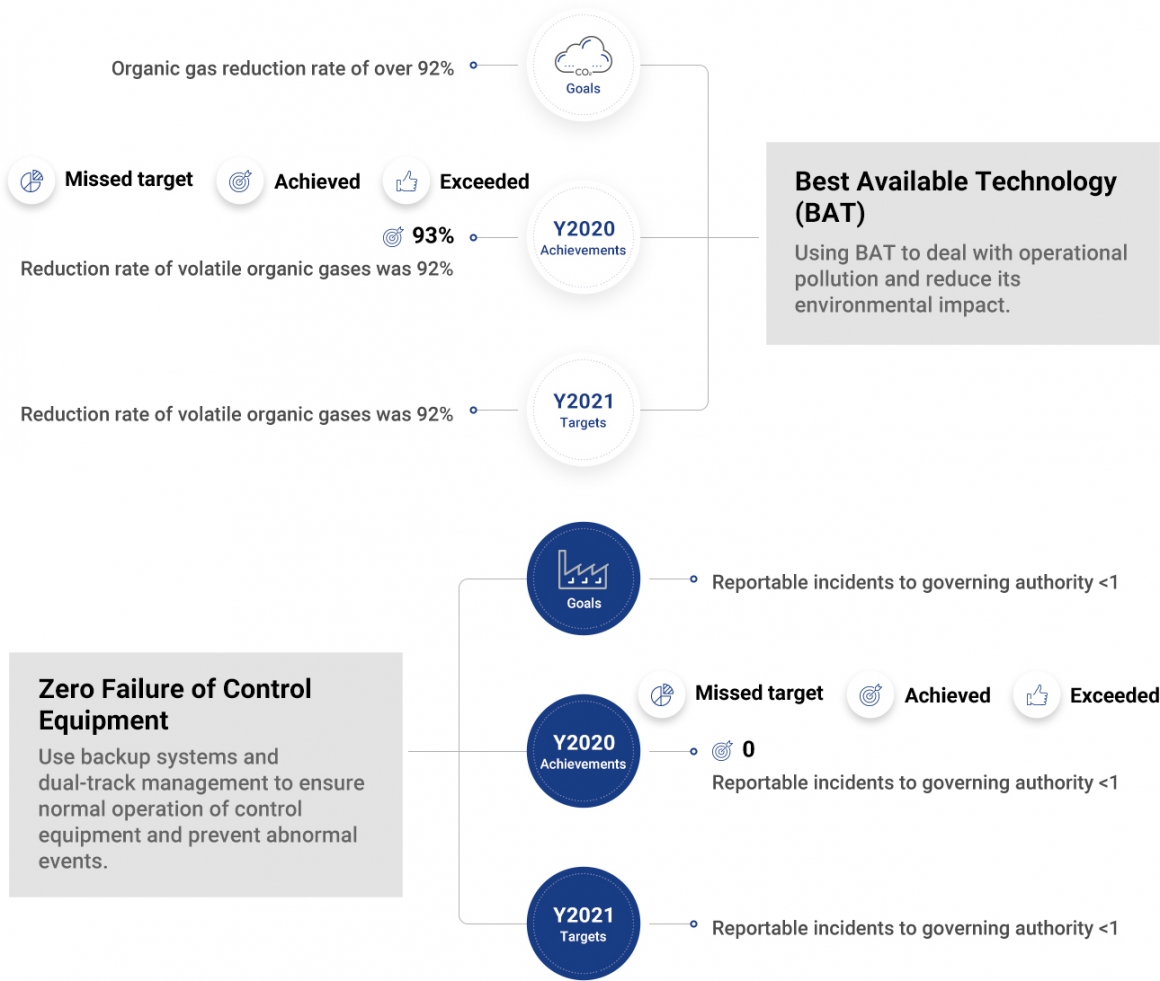

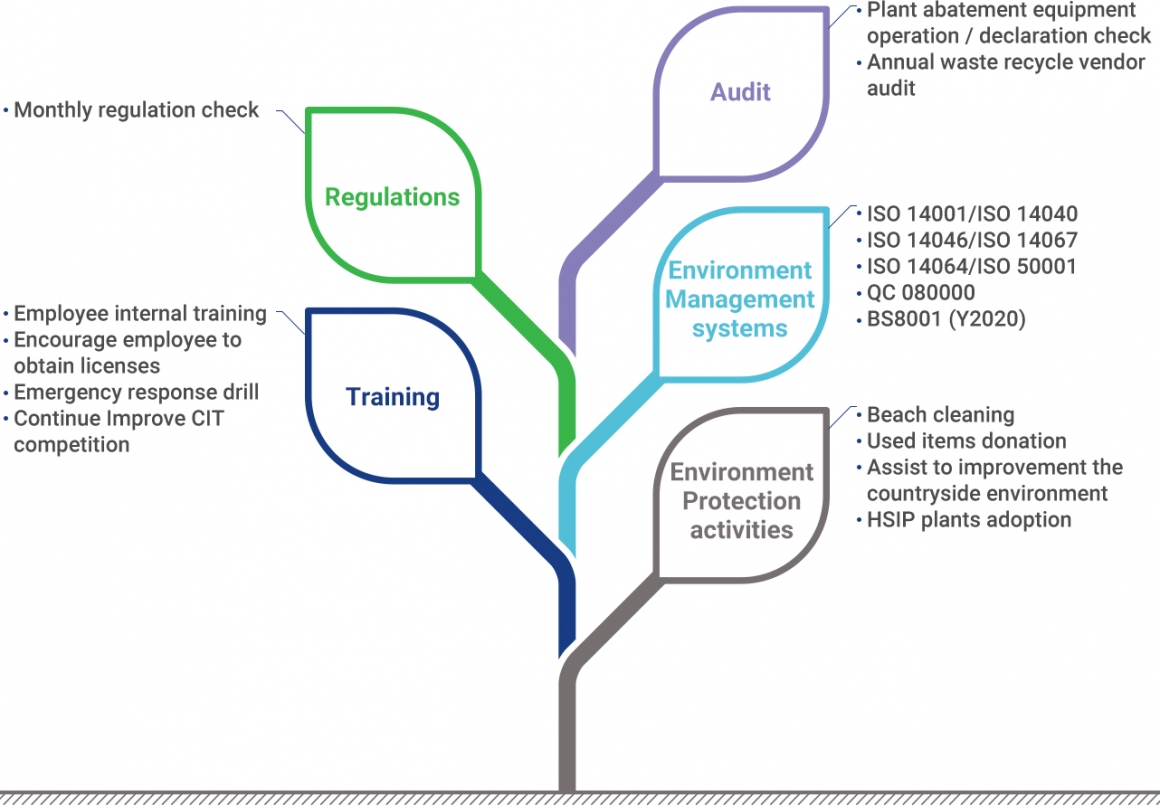

Air Pollution Control

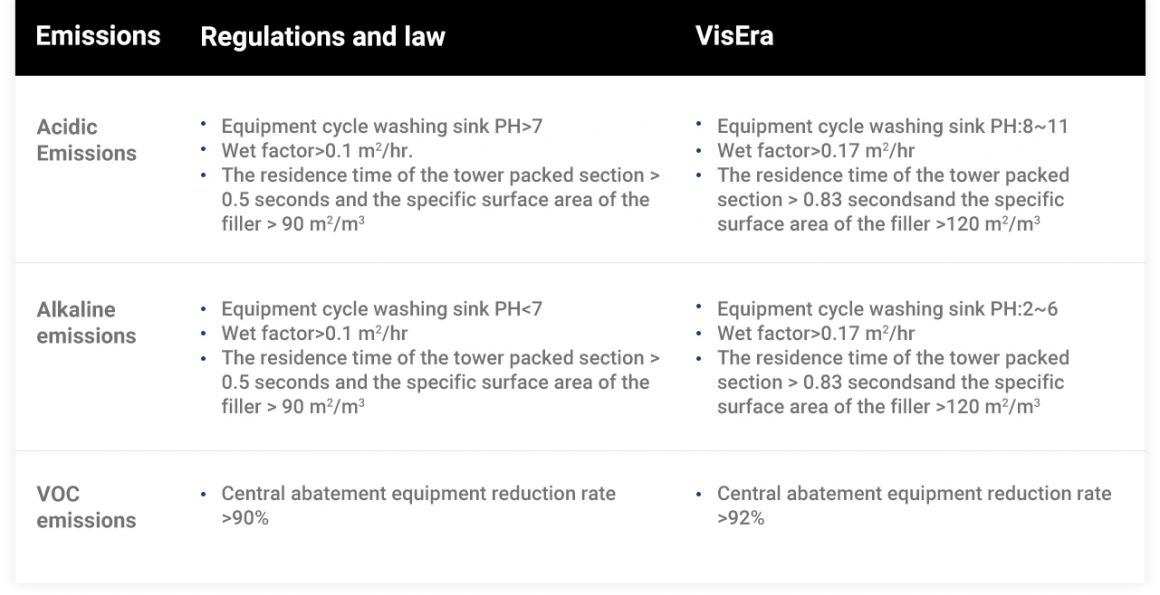

Superior to Regulations Air Pollution Control Methodology

VisEra air pollution control capacity satisfies the Taiwan's "Semiconductor Manufacturing Air Pollutant Control and Emission Standards" and "Fixed Air Pollutant Emission Source Standards". In order to ensure the stable operation for 24 hours and 365 days of the pollution control equipment, all air pollution control equipments are equipped with at least one backup system (N+1 design) and install un-interruptible power system as power backup. Achieve the management goal of zero failure of the control equipment to ensure stable and continuous pollution monitoring. In addition, VisEra also installed an automatic monitoring equipment to keep the effectiveness of the exhaust gas treatment of each system. The relevant information is also returned to the factory on-duty station and the industrial safety emergency response center. By dual independent monitoring system to ensure the chimney exhaust gas meets the regulations. Under the early warning control mechanism and real time response, no abnormal events need to report to the competent authority in 2020.

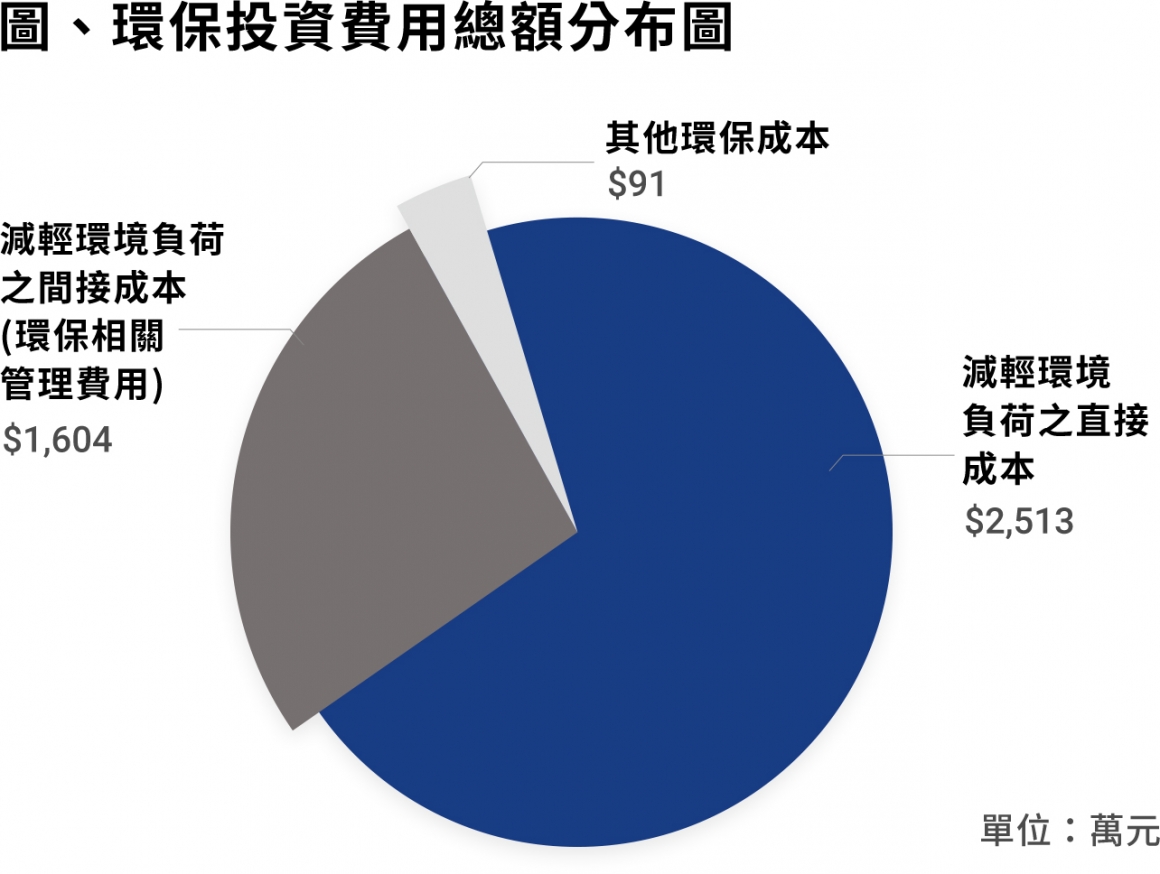

Environmental Accounting

VisEra goal is to facilitate coexistence and mutual prosperity between business and environment. Aiming to implement continuous environmental protection projects. We hope to protect our environment while increasing the Company’s value. We paid NT$53 million for environmental pollution control devices. Other investment costs are as below.

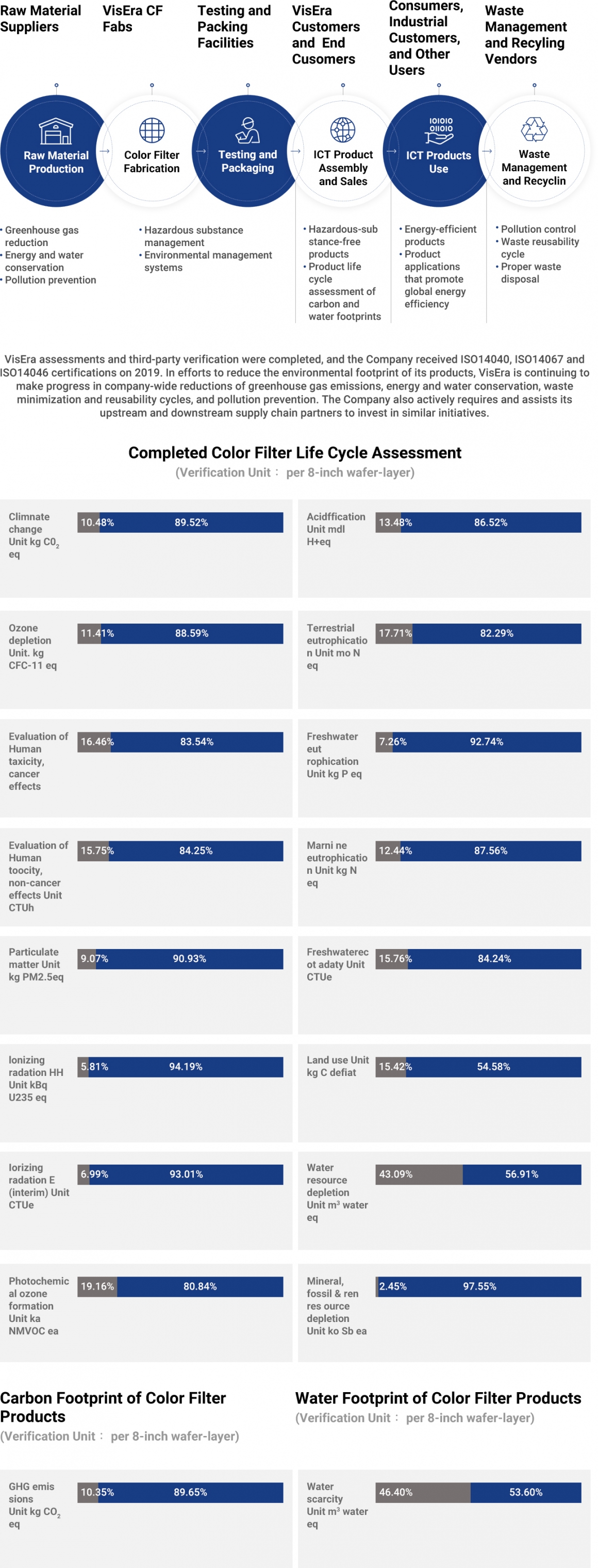

Product Life Cycle Environmental Impacts Consideration

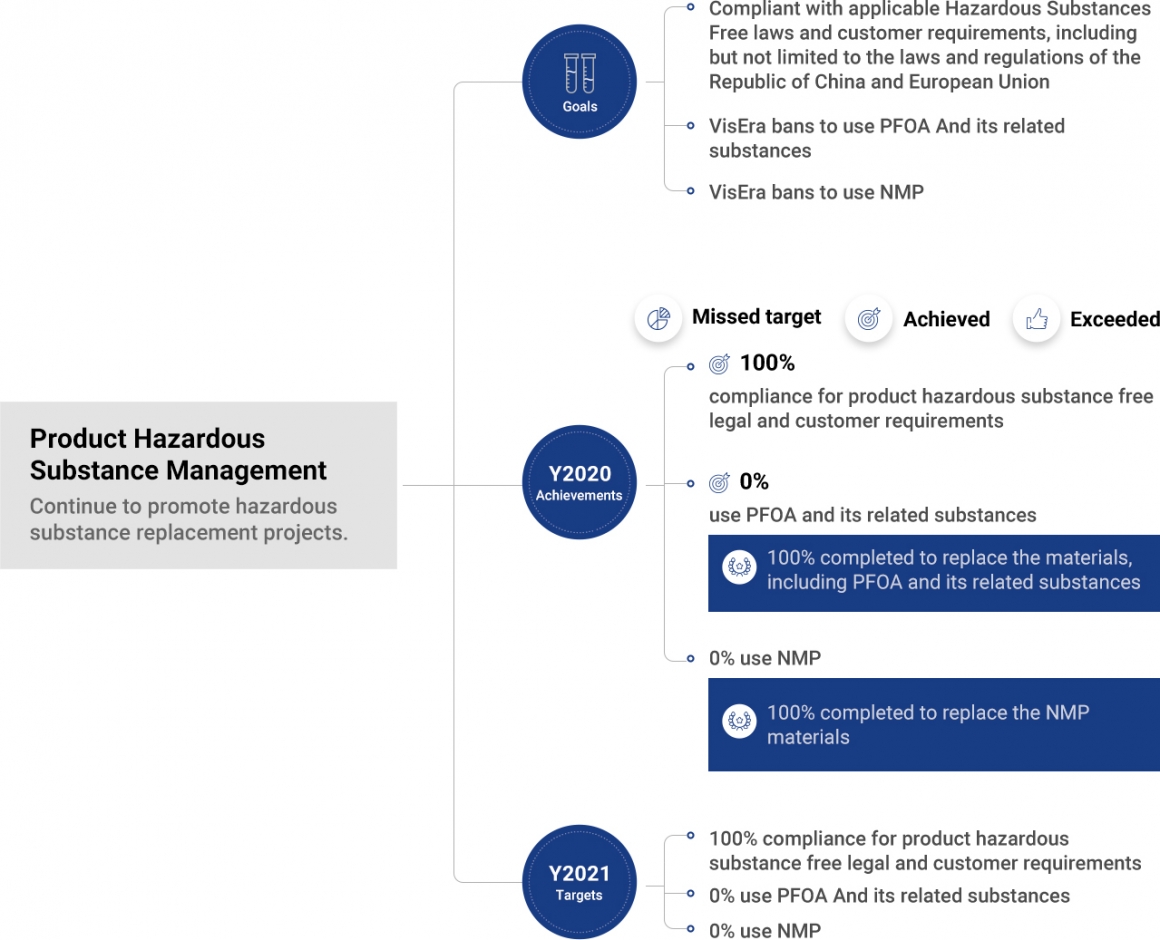

Product Hazardous Substance Management

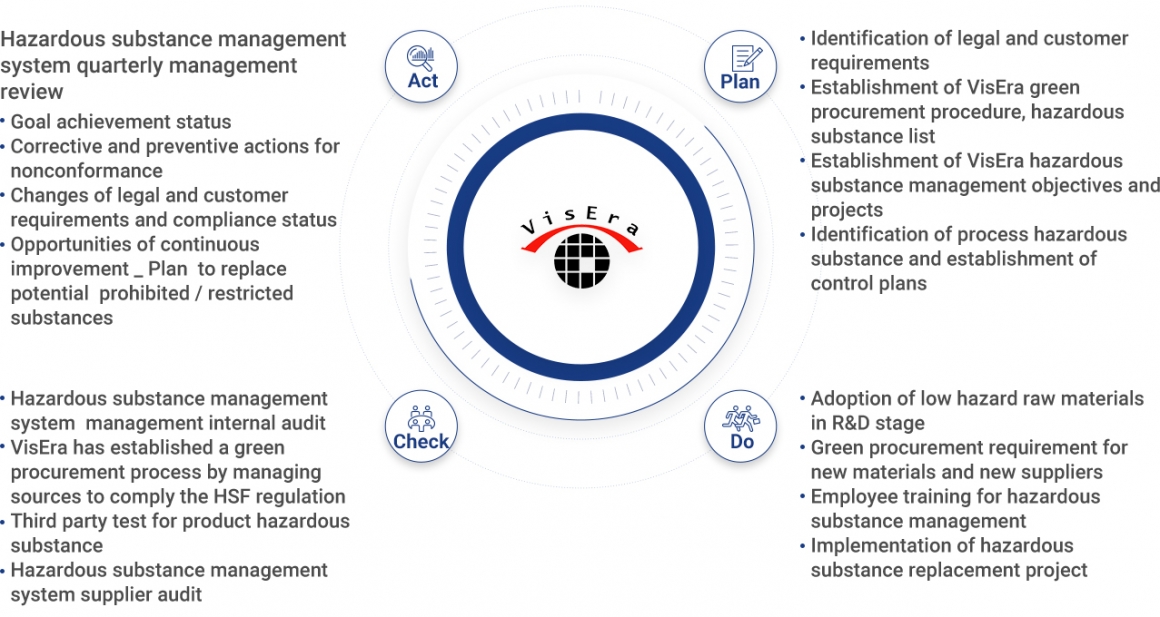

VisEra Hazardous Substance Management Process

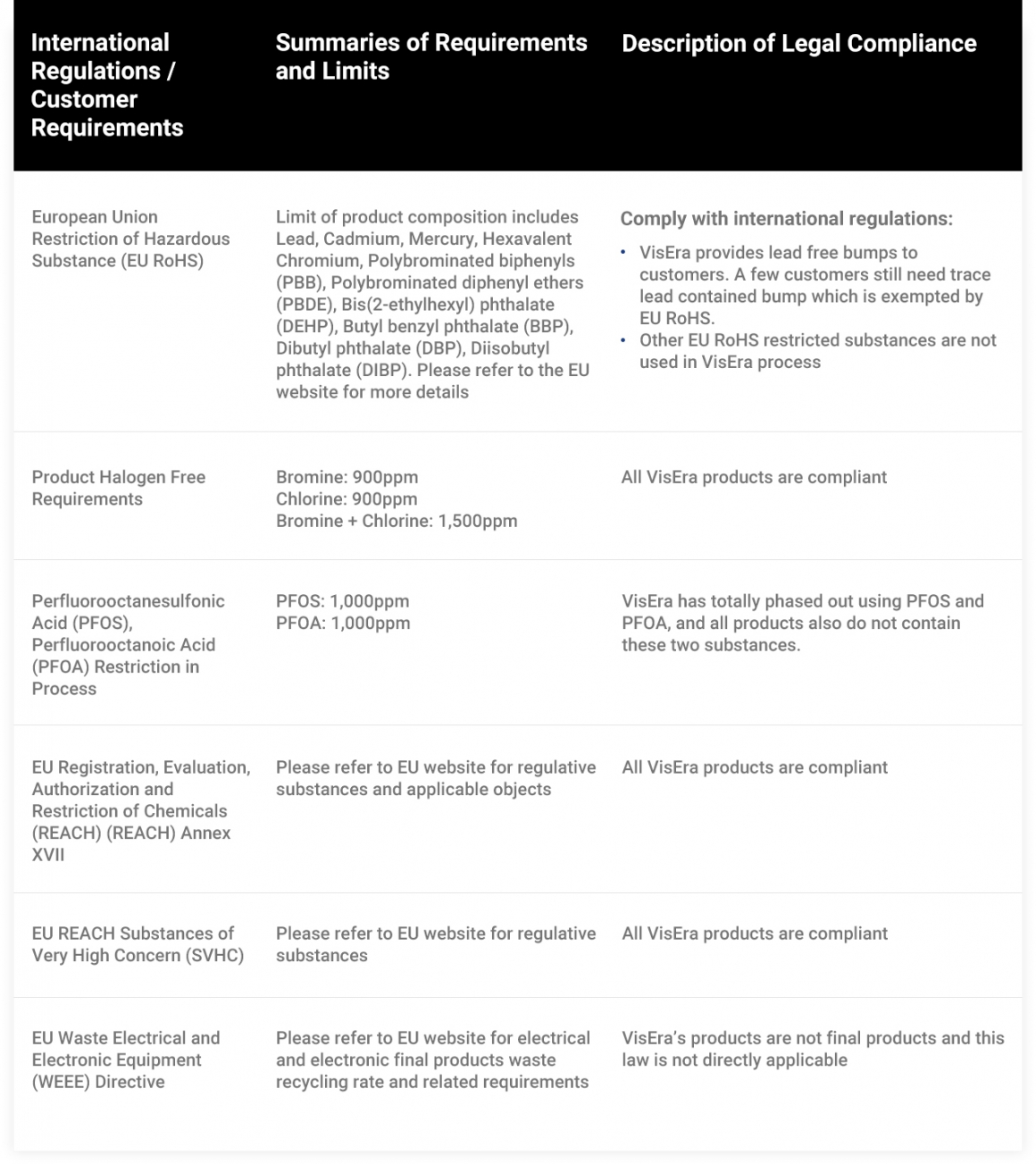

Product Hazardous Substance Management is Compliant with or Surpassed International Regulations

Occupational Safety and Health

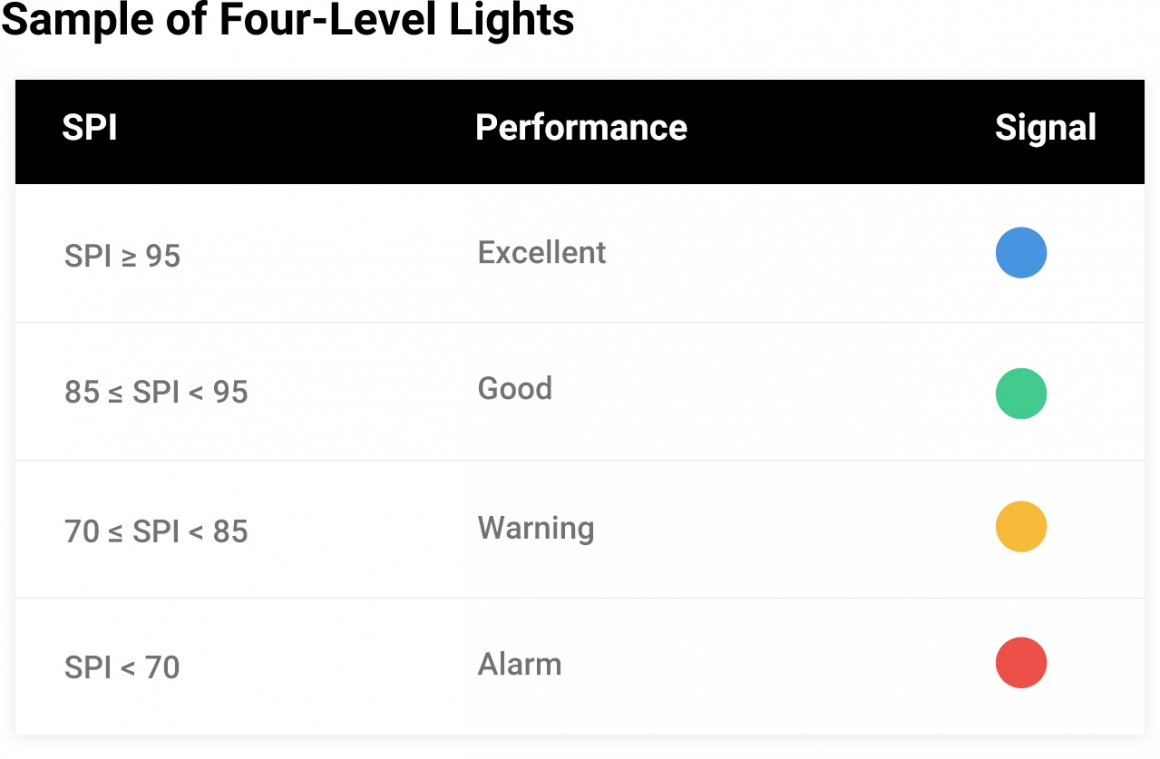

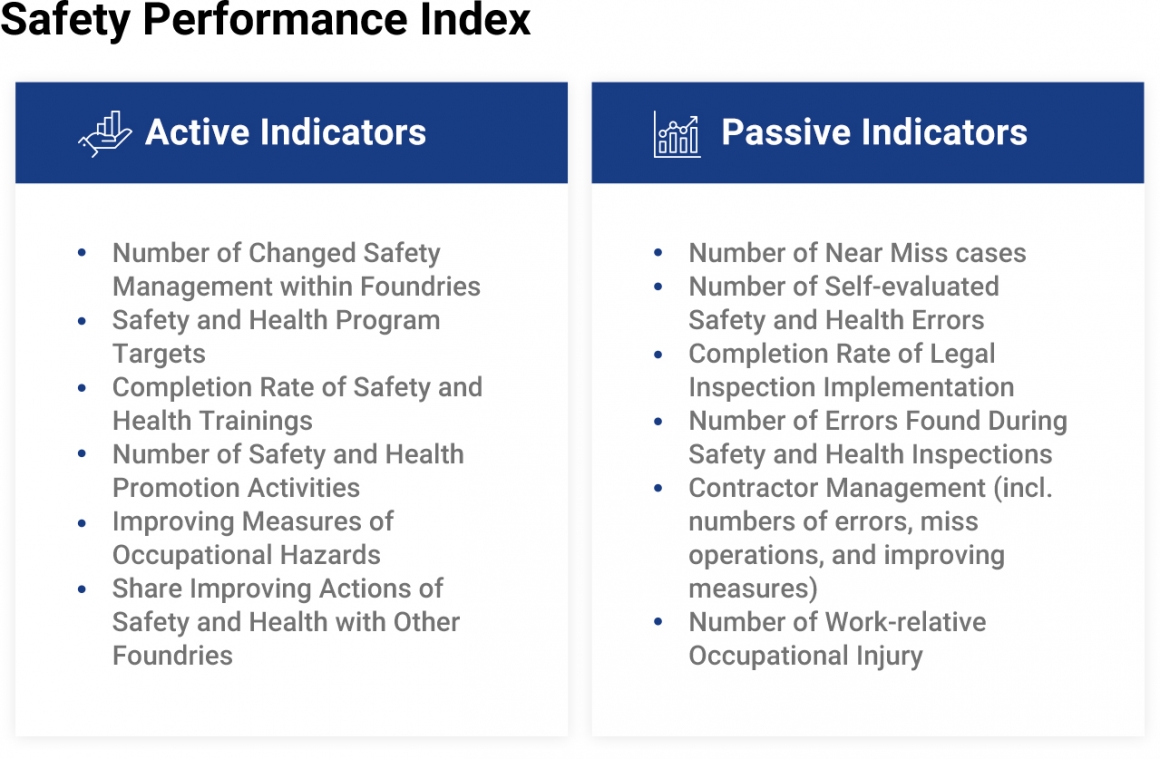

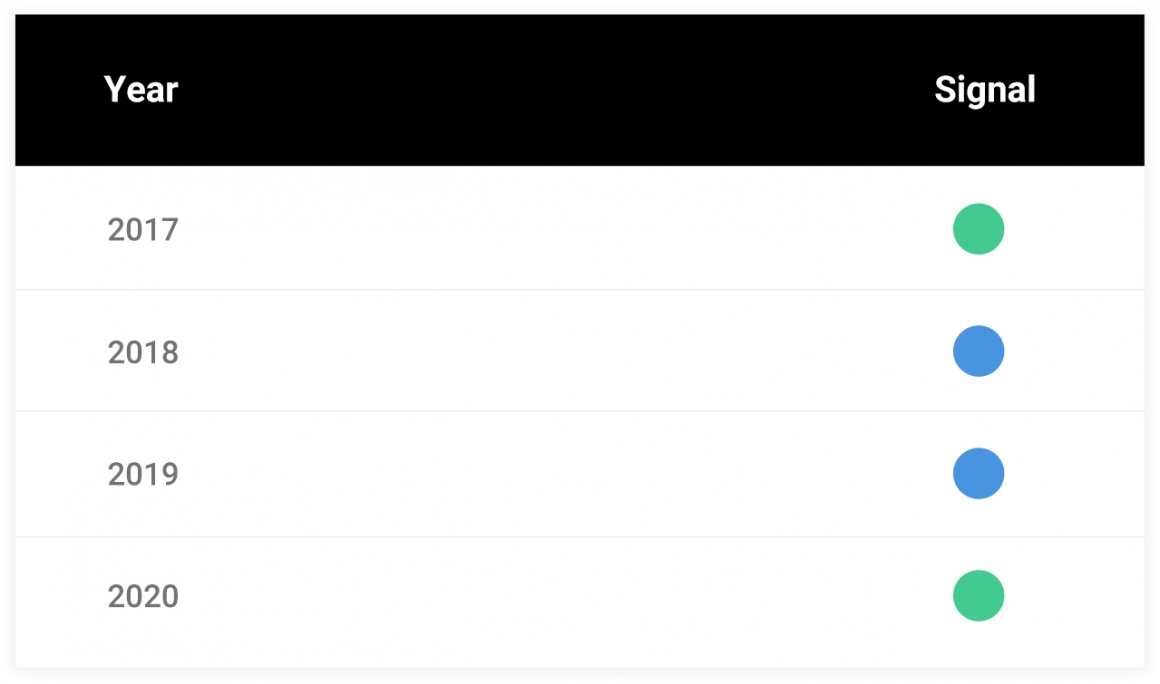

The standard procedures are established in accordance with the Occupational Safety and Health Act, as well as the requirements of the Occupational Health and Safety Assessment Series (ISO 45001), with reference to advanced domestic and international safety and health practices.To ensure that relevant safety and health procedures have been solidly implement, benchmark tsmc model, a Safety Performance Index(SPI) system is formulated ,the daily results of carrying out safety and health practices in plants based on quantification management can then be obtained. SPI includes leading indicators and lagging indicators. SPI adopts a “management mechanism using blue, green, yellow and red lights as indicators. Result is getting better.

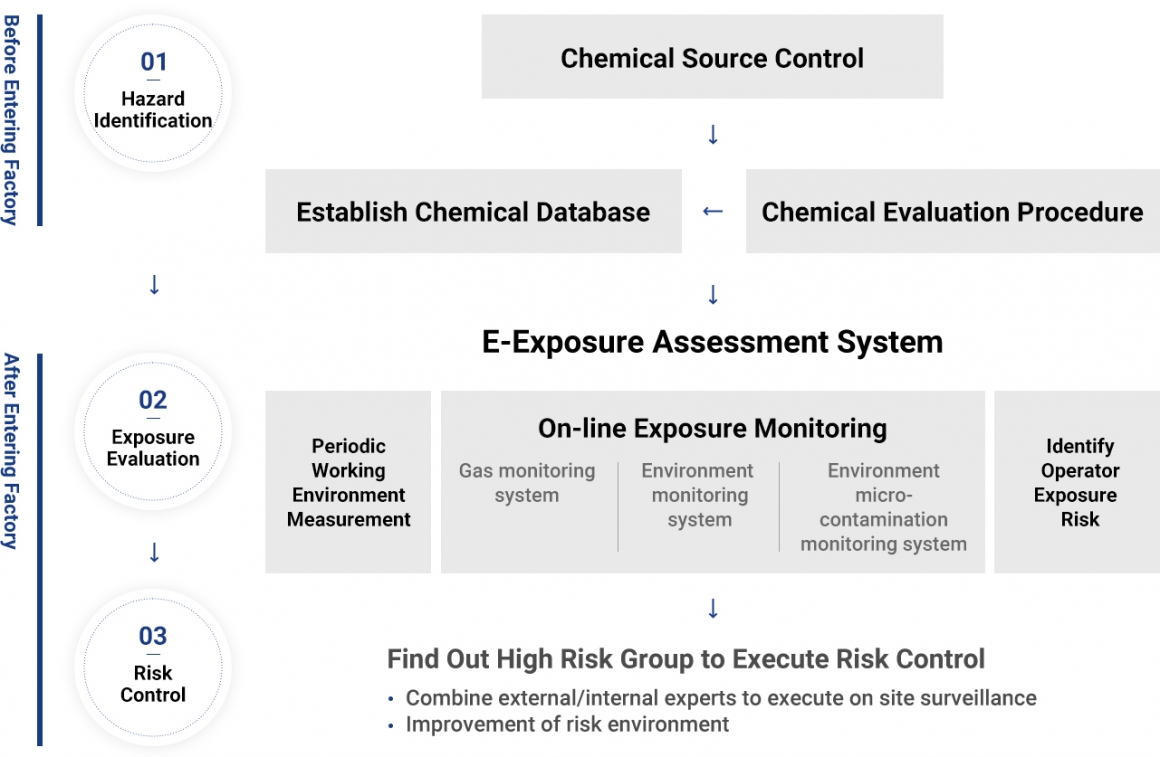

Chemical management program

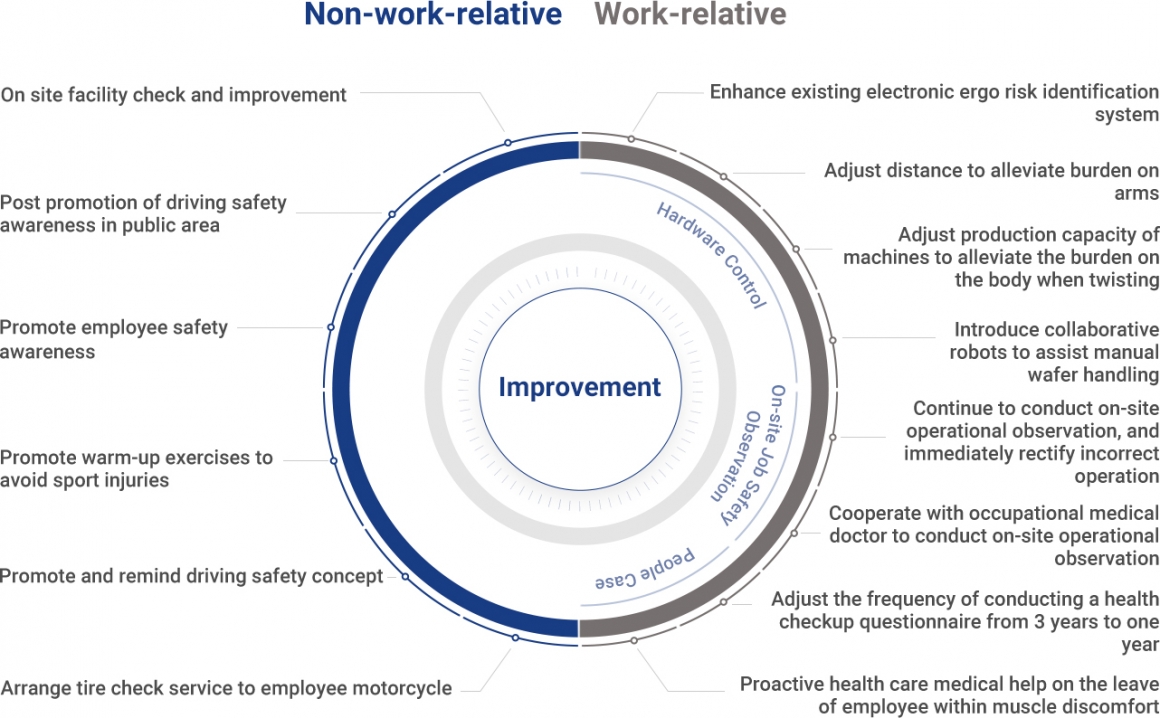

Introduce Occupational Medical Experts to Perform On-site Observation

Result

Annual award record